Mobile Plant Escape hatches

Most mobile plant usually have at least two ways to get out of the cab when there is an emergency the main door to the cab and a secondary escape hatch, often positioned in the roof or to the rear of the cab. A recent report and some follow up checking by the crew supervisor have highlighted that some escape hatches are not fit for purpose! This emphasises the risk that a relatively minor incident could become much more serious if, for example, after tipping over the machine caught fire or submerged in water.

Is Your Hatch in Working Order?

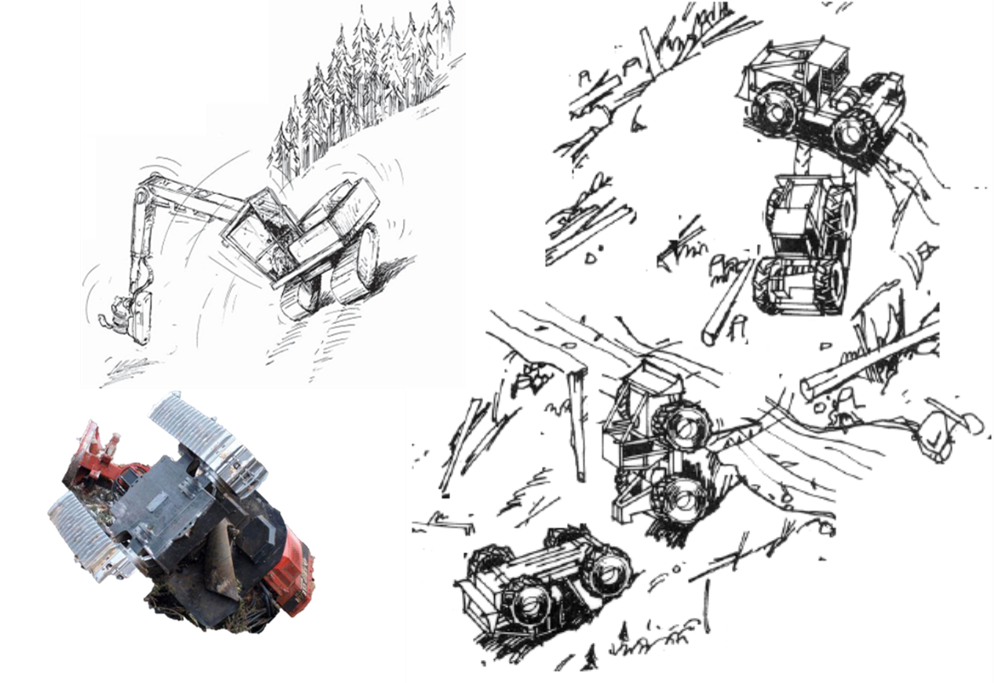

FIPS # 8529 As the operator walked the machine it slipped sideways (on Rhyolite) a few metres and tipped over on to its side. After the rollover incident the crew found that the bolts on the escape hatch had rusted shut making it unusable.

Check Your Hatches Each Shift!

Operators should check hatches before each shift taking care to clear away any debris. Bent or damaged hatches, corrosion or damaged seals, over tight bolts, or even heavy repainting can make escape hatches difficult or impossible to open. Check that the external cab (OPS) does not block the hatch especially following minor damage or modifications. It is a good idea to document these checks in the record keeping system.

View this article in Safety Bulletin 107