Systematic Attention to Machinery Management Urged

The importance of systematic maintenance and proper fault management of machinery in workplaces has been highlighted today at the sentencing of the Lyttelton Port Company (LPC). Companies using any machinery in their work must ensure the machinery is maintained according to manufacturer instructions and must have an effective system in place to identify faults. Chief Inspector Keith Stewart - August 2016.

His comments follow an investigation and prosecution of LPC after the Rail and Maritime Union raised concerns with the company, and later WorkSafe NZ, about the use of a cherry picker (a mobile elevated work platform) at the port. Issues about the use of the cherry picker were raised with the company the day after a fatality occurred on a scissor lift (another form of mobile elevated work platform) at the port. Two weeks later, a mechanical fault with the cherry picker was discovered and it was not removed from service.

No Injuries Needed For A Prosecution!

WorkSafe investigated the complaint and found that while there had been no injury to workers, there were multiple failings in the company's management of the cherry picker that could easily have led to a worker being injured, Mr Stewart said. LPC was fined $75,000.

Lyttelton Port Company - Worksafe NZ Investigation!

The WorkSafe NZ investigation found the practicable steps available included:

-

Daily pre-start up checks

-

An effective system for identifying machinery faults and addressing such faults in a timely manner.

-

Taking faulty machinery out-of-service until assessed by a qualified person; repaired or replaced if necessary; and made safe for use

-

Maintaining machinery in accordance with its operating manuals.

Taking Reasonably Practicable Steps in Forestry!

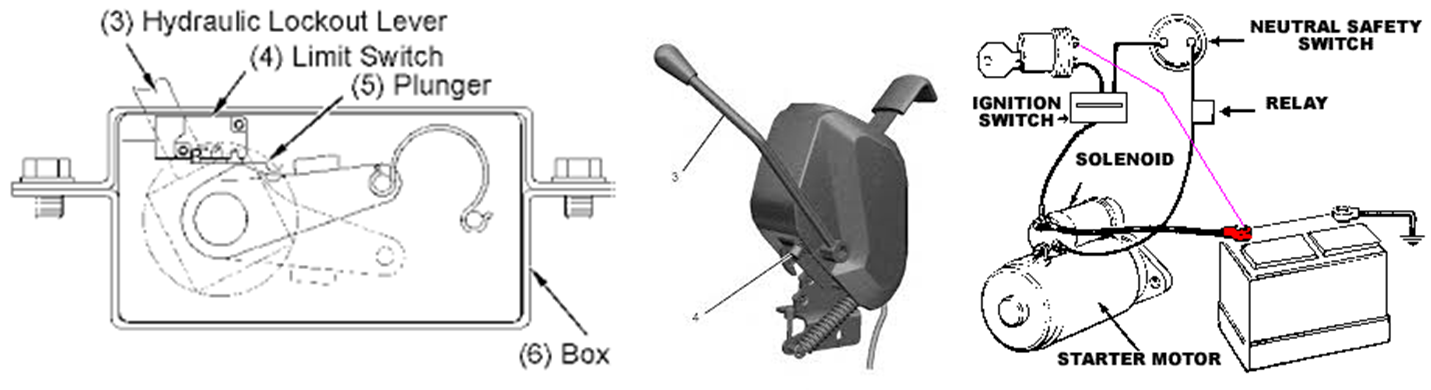

According to the ACoP (6.2.1), machinery shall be operated to the manufacturer's specifications, and (6.5.2) that alterations to safety-critical structural, mechanical and electrical components of mobile plant outside the manufacturer's specifications shall either be approved by the manufacturer (or their agent) or a Chartered Professional Engineer.

NB: The terms: Safety Critical, Operating Manual (OM) & Manufacturer's Specifications!

What can you (as a Contractor, PCBU or Worker) do?

- [Ensure you have the appropriate/matching OM¹ for each machine at the work-site.

- Check what the OM states about maintenance schedules and safety devices.

- Ask the supplier/hire company/owner to demonstrate how the safety devices work.

- Maintain a list and regularly check the operation of safety devices for each machine.

- Immediately correct machinery faults or take the machine out-of-service.

- Train operators in maintenance routines² and on how to check all the safety devices.

- Do not permit faulty machines to work at your worksite – remove them from service.

- Look after OMs that come with new machines and pass them on if/when the machine is sold. Request an OM from the manufacturer (or its agent).

- Have a specific list of safety feature for each machine at your work-site even if you have two or more machines that are the same make and model.

View this article in Safety Bulletin 101