Maintenance MTIs Continuing

Maintenance injuries featured strongly in our 2017 data and the trend appears to be continuing!

INC_634 22/11/17 MTI Using a sledgehammer on the skidder track, a piece of steel ricocheted off and into the worker's forearm.

INC_636 20/12/17 MTI While removing the belly plate from under the machine, the plate, which was twisted, sprung down, cutting the operator's left hand (stitches required).

INC_674 19/01/18 MTI A breaker-out was splicing an eye onto the main rope when the sharp end of a rope strand caught and cut his forearm (stitches required).

Maintenance considerations

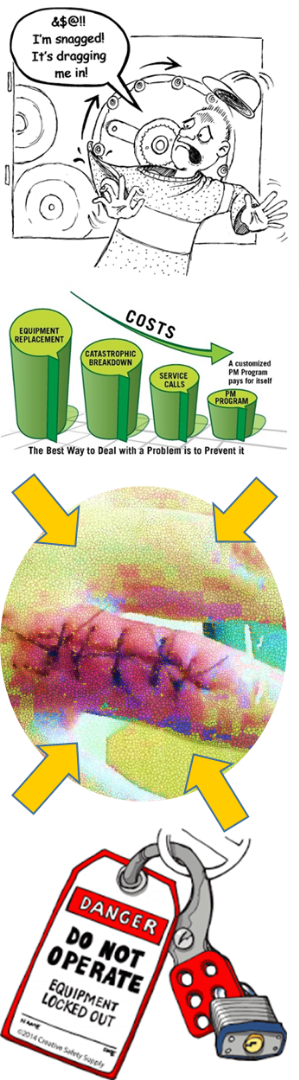

Wear the correct PPE: Maintenance injuries often occur because the correct PPE is not worn. Several sets of gloves may be required, especially when working with oils and grease.

Never complete maintenance alone: Kiwis will often attempt to complete a job alone rather than ask for help. However, a second person can be used to help with tricky situations e.g. work in confined spaces. This person can also run additional safety checks, ensuring machinery is properly isolated and de-energised.

Tools: Use the correct tools for the job and don't leave tools lying around where they can fall and injure other workers.

Clean surfaces before working on them especially remove oil.

Use a maintenance schedule regular maintenance and replacement schedules may prevent break-downs and reduce risk.

For more information and Preventative Maintenance Tips for Forestry Machines please click of this hyperlink: https://www.cat.com/en_US/articles/support/forestry/6-preventative-maintenance-tips-for-forestry-machines.html

View this article in Bulletin 111