LTI Critical Risk. Maintenance

After tree felling and pruning accidents, the Q4, 2017 IRIS data summary notes there were ten lost time Maintenance-related injuries. Of these 10, six were sustained to either the hand or foot area of the body. Two were associated with the use of a sledgehammer.

If we include setting up signage, re-spooling wire rope and refuelling, then around 30% (11/35 in 2017) of the Company's harm accidents are also occurring in the maintenance category.

Here are some things we have learned in our investigations to make maintenance safer:

- Stop the engine and release all hydraulic pressure, engage all safety lock-out devices.

- Keep pockets free of things that can fall out and don't leave items where they can fall.

- Never work below an object that could fall, use jack stands as stable supports.

- If possible, always complete maintenance as a team even if one person stands guard. If maintenance involves a running engine always use two people, one to shut the motor down if required.

- Do not try to lift large, unwieldy, slippery or heavy objects by yourself get help!

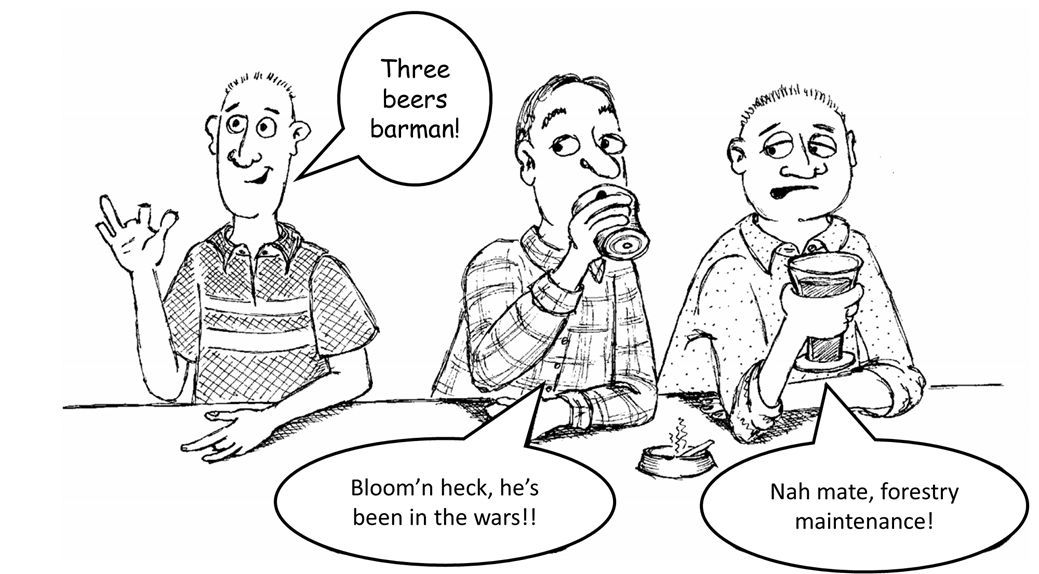

- Use the correct tool for the job. Foolishness is trying to undo a nut with a sledgehammer!

- Wear the appropriate PPE, gloves especially and change these as often as needed.

- If outside of your capability call in an expert having the right tools and training.

View this article in Safety Bulletin 112