Energy Sources - Cable Harvesting

FIPS 8760 12/04/17 - Serious Harm, LTI.

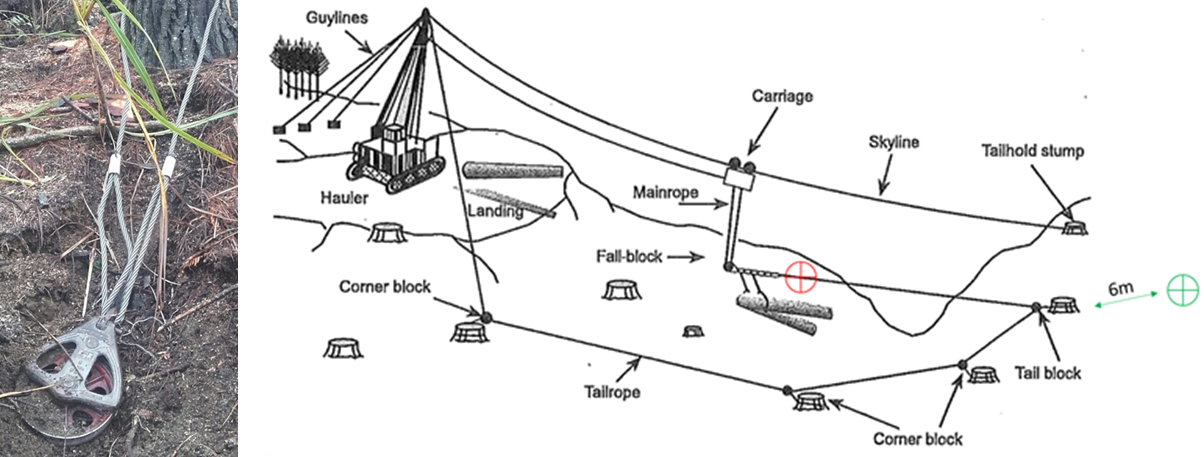

A breaker-out had moved to the designated safe retreat position, which was 6 meters behind the tail block (see image below). During the in-haul, the tail rope broke, fell to the ground and started coiling up-hill.

As the rope moved through the block, it changed its line and direction to where the breaker-out was standing. Protecting himself, he lowered his head and the rope connected his hardhat knocking the rim down causing fractures in his face.

NOTE: The red cross indicates the approximate location of the break in the tail-rope and the green cross the approximate location of the breaker-out when struck.

Root Causes, Background Information and Findings:

The investigation showed the system, equipment and hauler setup to be compliant. The main rope had no signs of fatigue both on the drum and in the area of the breakage. The tension monitor was away for recalibration at the time, however, there was no evidence of overloading discovered. The breaker-out was fully qualified (1258). He can thank his hardhat for saving him from more serious injuries (actually, the third time a hardhat has saved a worker this year). While there were no breaches of best practice, or rules, PF Olsen's Zero Tolerance Committee (ZTC) is currently reviewing whether a certified rope inspection would be necessary for all ropes aged between 12-18 months. Secondly, if the Company should specify the position a breaker-out would stand in relation to a working block. It will report on its findings shortly.

View this article in Safety Bulletin 107